The evolution of bat technology in the men's softball market took a significant turn in 1999 with the introduction of composite bats. Players quickly noticed that these bats exhibited enhanced performance, specifically hitting the ball farther after approximately 500 hits. However, the waiting period for this improvement seemed too long for some players, leading to the adoption of various break-in methods.

Players experimented with unconventional approaches, such as hitting bats against trees or posts, using rubber mallets, applying pressure in a vice, and even rolling the bat over with a car tire. Among these techniques, bat rolling emerged as the most effective accelerated break-in method. Originating in California in 1999, bat rolling was pioneered by a 17-year-old named "Chepe" who employed an English Wheel Machine. This innovation laid the foundation for the advanced machines we have today.

The initial bat rollers were limited to perpendicular rolling, restricting the contact of rollers with the bat along the barrel's length. Over time, machines evolved into dual-action parallel and perpendicular models, with Juiced Inc. introducing the first such machine in 2008.

In 2010, the roller material also underwent a transformation. While nylon was the preferred substrate, Juiced Inc. introduced a more robust material called Delrin® plastic. This marked a significant improvement, allowing bats to be rolled at higher pressures without slippage or leaving undesirable marks. Bat manufacturers adapted their production methods in 2011, with Easton leading the way by creating bats designed to "surface crack" diagonally along the bat due to extreme flex, either from rolling or extended use.

The durability of bats changed post-2011, as today's bats feature a more delicate top layer of composite material compared to the robust bats of the past. Pre-2011 bats could last 3 to 5 years with 5000 to 7000 hits, but the introduction of Delrin® rollers caused creases in the composite's top layer due to the denser roller material.

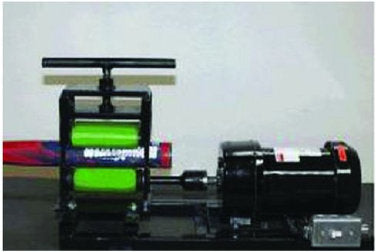

In response, Panther Machines experimented with a slightly softer urethane in 2011, aiming to break in bats without creating surface cracks or creases. By 2012, Easton, Miken, and Worth had adopted this new polymer. Panther Machines further enhanced bat rolling with the creation of an electric bat rolling machine in 2012, providing a distinct advantage to bat rollers.

Today's bats often have a surface layer prone to cracking under excessive pressure during rolling. This has led to the emergence of alternative bat break-in techniques, including heated rolling, the Barrel Compression Technique (BCT) machine, and the traditional natural break-in process. As composite materials continue to advance, new challenges arise in the quest for maximum performance from baseball and softball bats.