What is the Purpose of a Barrel Compression Tester?

The Purpose of a barrel compression tester from the G4 SSL website “The SSL portable barrel compression fixtures or bat testers were developed for the softball and baseball industry to measure the barrel stiffness of a bat. The barrel compression of a bat correlates to its performance. The lower the compression, the better the bat will perform” (But this is not always an accurate statement).

Per the G4 SSL website the applications are:

“The devices are used to determine when a bat has exceeded its intended life and also reveals when bat barrels have been tampered with (i.e. when a bat has been rolled or when the bat barrel has been shaved). The tester is commonly used to test bats before games, tournaments, and is also used for quality control purposes”.

So basically the USA (ASA), NCAA, and the USSSA have come up with set standards of barrel compressions that deem a bat unusable or usable in their sanctioned events. There is not a lot of literature on the procedures for barrel compression testing but the G4 website does have instructions. There is a reference rod that allows the bats to be measured at the 6 inch location on the barrel. The barrel of the bat is butted up to that rod and cannot touch the sides of the compression tester frame. The pressure gauge is then set to zero (USSSA) or 500 (ASA/NCAA). Then the lever is pulled up to measure compression.

What is a passing Barrel Compression Number?

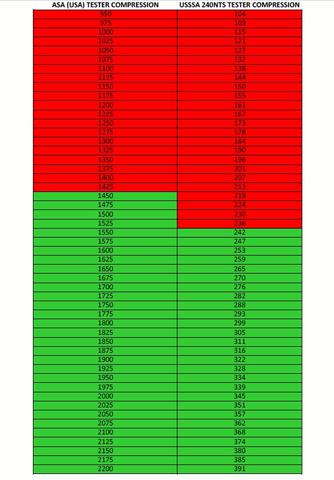

In ASA Slow Pitch events 1450 psi and above are passing.

(ASA Exceptions to this threshold HERE)

In ASA/NCAA Fast Pitch events 1550 psi and above are passing.

(ASA/NCAA Fast Pitch Exceptions to this threshold HERE)

In USSSA Slow Pitch events 240 and above is passing.

In NCAA play:

• Metal bats: 1250 lbs.

• Composite bats: 1000 lbs.

• Non-linear*: 800 lbs.

*The Rawlings Quatro, Rawlings Quatro Pro, Rawlings Quatro Max, Rawlings Quatro IX and Mizuno PWR CRBN models are currently the only BBCOR models with a barrel compression approved for non-linear bats.

The site also has a USSSA testing session before a Major Men’s slow pitch softball tournament. (A couple things I find odd about the video is that the tester places his hand on the tester when pulling up the lever to lock it in place. My research verifies that extra pressure on the top of the machine can change the reading of the gauge by as much as 65psi. The other issue is the failing of a bat on the first test and it is unusable, there are just too many variables. I mention this only because the machines have a + or – of 100 psi when calibrating but not when testing. The gauge also has a lag when getting to the zero. This is a little hard to explain but I will try; the needle does not respond instantaneously when moved, it kind of lags and there is some play from the needle to the gauge wheel. This “play” or “lag” can cause discrepancies in your reading. Even with the machine’s range of +/- 100 psi and human error the compression tester is still a great way to keep unusable bats out of sanctioned play.

ASA to USSSA Barrel Compression Conversion Chart